vertical lift versus radial lift skid steer The most common question asked by skid steer customers is, “Which style of . Your JCB E-TECH machine has a charging option to suit your application, including single-phase and three-phase charging solutions, and fast charge options to get you ready to work even faster. HTD-5E Dumpster Charging Solutions 75min charge time with a standard 230v lead 2hrs 45min charge time with 110V lead

0 · vertical vs radial lift steer

1 · vertical lift vs radial lift

2 · vertical lift steering wheel

3 · vertical lift steer

4 · vertical lift skid steer

5 · vertical lift loader

6 · radial vs vertical skid steer

7 · radial lift skid steer

The JCB Hydradig 110W is a versatile and manoeuvrable wheeled excavator with a low tailswing, a 109hp EcoMAX engine and a CommandPlus cab. It offers best-in-class stability, visibility, comfort and serviceability for a range of attachments and jobs.

Radial-arm skid steers are good for excavating, grading and digging below .

Vertical lift skid steers feature a lift path that moves straight up and down, .A vertical lift loader makes loading dump trucks easier. The machine’s maximum height allows . Radial-arm skid steers are best for excavating, grading and digging below . The most common question asked by skid steer customers is, “Which style of .

The difference between vertical lift and radial lift involves the path that the load . At their core, both radial-lift and vertical-lift skid steers excel in tasks like loading, .

vertical vs radial lift steer

Learn the differences and advantages of radial and vertical skid steer loader . Learn the differences and similarities of radial lift and vertical lift skid steer loaders, and how to choose the right one for your job. Radial lifts are better for digging and grading, while vertical lifts are better for stacking and drilling. Radial-arm skid steers are good for excavating, grading and digging below grade. Vertical-lift machines are ideal for material handling.

Vertical lift skid steers feature a lift path that moves straight up and down, providing higher reach and lift capacities compared to radial lifts. This design is particularly beneficial for tasks that involve loading materials into trucks or stacking pallets.A vertical lift loader makes loading dump trucks easier. The machine’s maximum height allows a bucket to reach completely inside a truck to dump the load. Because the bucket on a vertical design rises and turns at the same time, your overall dimensions remain constant. Learn the difference between radial and vertical lift skid steers and compact track loaders, and how to choose the best one for your project. Compare the pros and cons, lift capacity, reach, stability, and visibility of each type of machine. Radial-arm skid steers are best for excavating, grading and digging below grade. Vertical-lift machines are ideal for unloading material off trucks and loading dirt into a dump truck. "It depends if they are loading and unloading flatbed trucks. For that, radial-lift is better.

The most common question asked by skid steer customers is, “Which style of skid steer is better, radial lift or vertical lift?” The answer is both. The choice between radial lift and vertical lift design on a skid steer or track loader depends entirely on the application.

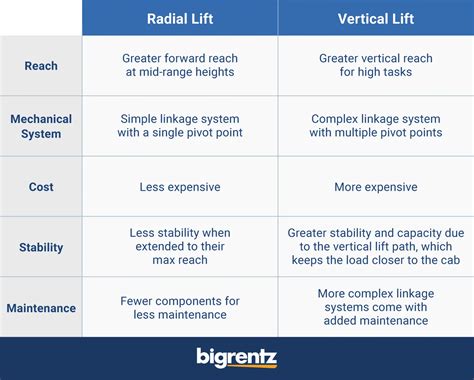

The difference between vertical lift and radial lift involves the path that the load takes as it is being lifted. This path is a direct result of the geometry of the skid steer (or compact track loader) arm. On a radial lift machine, the load follows a curved path. At their core, both radial-lift and vertical-lift skid steers excel in tasks like loading, debris clearing, and site leveling. The primary difference lies not in their capabilities, but in how they apply them, particularly in their lift path geometries. Learn the differences and advantages of radial and vertical skid steer loader designs for various applications. Radial loaders are simpler, stronger, and more stable, while vertical loaders are more versatile, balanced, and have higher capacity. Learn the differences and similarities of radial lift and vertical lift skid steer loaders, and how to choose the right one for your job. Radial lifts are better for digging and grading, while vertical lifts are better for stacking and drilling.

Radial-arm skid steers are good for excavating, grading and digging below grade. Vertical-lift machines are ideal for material handling. Vertical lift skid steers feature a lift path that moves straight up and down, providing higher reach and lift capacities compared to radial lifts. This design is particularly beneficial for tasks that involve loading materials into trucks or stacking pallets.

A vertical lift loader makes loading dump trucks easier. The machine’s maximum height allows a bucket to reach completely inside a truck to dump the load. Because the bucket on a vertical design rises and turns at the same time, your overall dimensions remain constant. Learn the difference between radial and vertical lift skid steers and compact track loaders, and how to choose the best one for your project. Compare the pros and cons, lift capacity, reach, stability, and visibility of each type of machine. Radial-arm skid steers are best for excavating, grading and digging below grade. Vertical-lift machines are ideal for unloading material off trucks and loading dirt into a dump truck. "It depends if they are loading and unloading flatbed trucks. For that, radial-lift is better. The most common question asked by skid steer customers is, “Which style of skid steer is better, radial lift or vertical lift?” The answer is both. The choice between radial lift and vertical lift design on a skid steer or track loader depends entirely on the application.

The difference between vertical lift and radial lift involves the path that the load takes as it is being lifted. This path is a direct result of the geometry of the skid steer (or compact track loader) arm. On a radial lift machine, the load follows a curved path.

At their core, both radial-lift and vertical-lift skid steers excel in tasks like loading, debris clearing, and site leveling. The primary difference lies not in their capabilities, but in how they apply them, particularly in their lift path geometries.

vertical lift vs radial lift

Choosing a mini digger just got easier with the new generation JCB 18Z-1. It has been designed and built to withstand the toughest of job sites.Buy Online: h.

vertical lift versus radial lift skid steer|vertical vs radial lift steer